In the world of water treatment and enhancement, bubble technology has gained significant attention. Among these, ultrafine bubbles (UFB) and microbubbles (MB) are often discussed. While both involve tiny gaseous cavities in a liquid, their fundamental differences in size lead to vastly different properties and applications. Understanding these distinctions is crucial for appreciating the unique power of ultrafine bubble technology, a field where Japan has established itself as a global leader.

Size Matters: Defining the Two Types of Bubbles

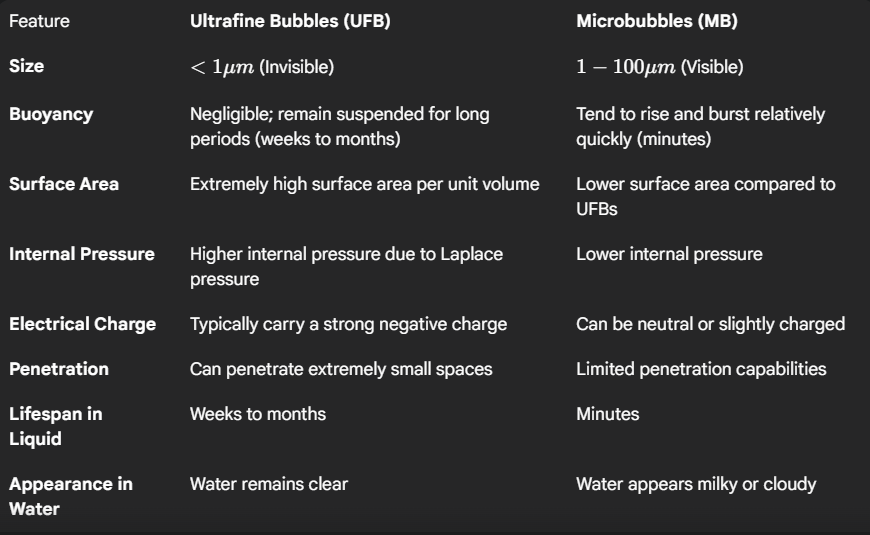

The primary differentiator between ultrafine bubbles and microbubbles lies in their diameter:

- Ultrafine Bubbles (UFB): Defined as bubbles with a diameter of less than 1 micrometer (<1μm). To put this in perspective, they are thousands of times smaller than a grain of sand and invisible to the naked eye.

- Microbubbles (MB): These bubbles range in diameter from 1 to 100 micrometers (1−100μm). While still very small, they are larger than UFBs and can cause water to appear milky or cloudy due to light scattering.

This significant size difference dictates their behavior and effectiveness in various applications.

Key Differences in Behavior and Properties

The Power of Ultrafine Bubbles: Unique Advantages

The distinct characteristics of ultrafine bubbles give them several key advantages over microbubbles:

- Long-Lasting Presence: Due to their near-zero buoyancy, UFBs remain suspended in liquids for extended periods. This prolonged contact time enhances their interaction with substances in the water, leading to more effective cleaning, disinfection, and hydration. This stability is a hallmark of advanced Japanese UFB technology.

- Exceptional Penetration: Their minuscule size allows UFBs to penetrate deep into microscopic pores, fibers, and crevices that microbubbles cannot reach. This is particularly beneficial in applications like deep cleaning of surfaces, enhancing soil hydration in agriculture, and improving absorption in skincare.

- Enhanced Interaction with Contaminants: The strong negative charge typically carried by UFBs attracts positively charged impurities such as dirt, oil, and bacteria. This electrostatic attraction facilitates their removal without the need for harsh chemicals, aligning with the global push for sustainable solutions – an area where Japanese innovation shines.

- Stable Cavitation Effects: While both types of bubbles can undergo cavitation (the formation and rapid collapse of vapor cavities), the stable and long-lasting nature of UFBs allows for more controlled and sustained effects, beneficial in industrial cleaning and other processes.

Applications Where the Difference Matters

The contrasting properties of UFBs and MBs dictate their optimal applications:

- Ultrafine Bubbles: Ideal for deep cleaning (industrial, domestic), enhanced hydration and growth in agriculture, improved water quality and animal health in aquaculture, advanced skincare and personal care products, and biofilm removal in pipes and systems. These are areas where Japanese UFB technology is at the forefront.

- Microbubbles: Commonly used for aeration in wastewater treatment, flotation in mining, and some surface cleaning applications where a shorter-lived, visual effect is acceptable.

Conclusion: Embracing the Invisible Power

While microbubbles have their uses, ultrafine bubbles represent a significant leap forward in bubble technology. Their incredibly small size, long lifespan in liquids, and unique electrical properties unlock a range of powerful applications across various industries. As a leader in this field, Japan continues to drive innovation and establish the standards for ultrafine bubble technology, offering solutions that are both effective and sustainable. Understanding the critical differences between UFBs and microbubbles is key to appreciating the true potential of this invisible revolution.